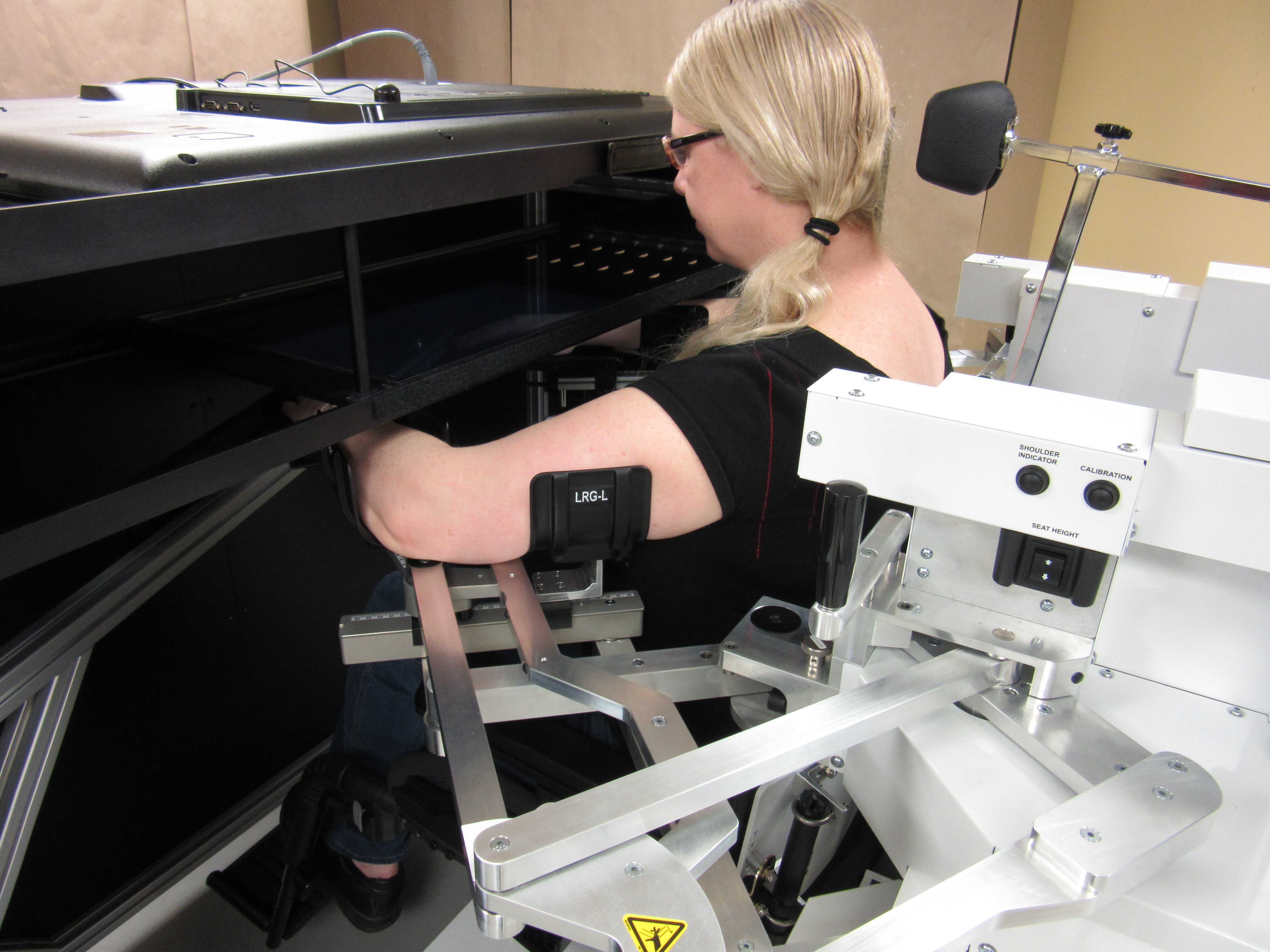

KINARM Exoskeleton Lab

BKIN Technologies is transforming the assessment of brain injuries by putting robotic technology in the hands of neuroscientists and clinician scientists around the world. KINARM Labs were invented by Dr. Stephen Scott, a professor in the Department of Biomedical and Molecular Sciences and the Centre for Neuroscience Studies at Queen's University in Canada.

Customer's Challenge

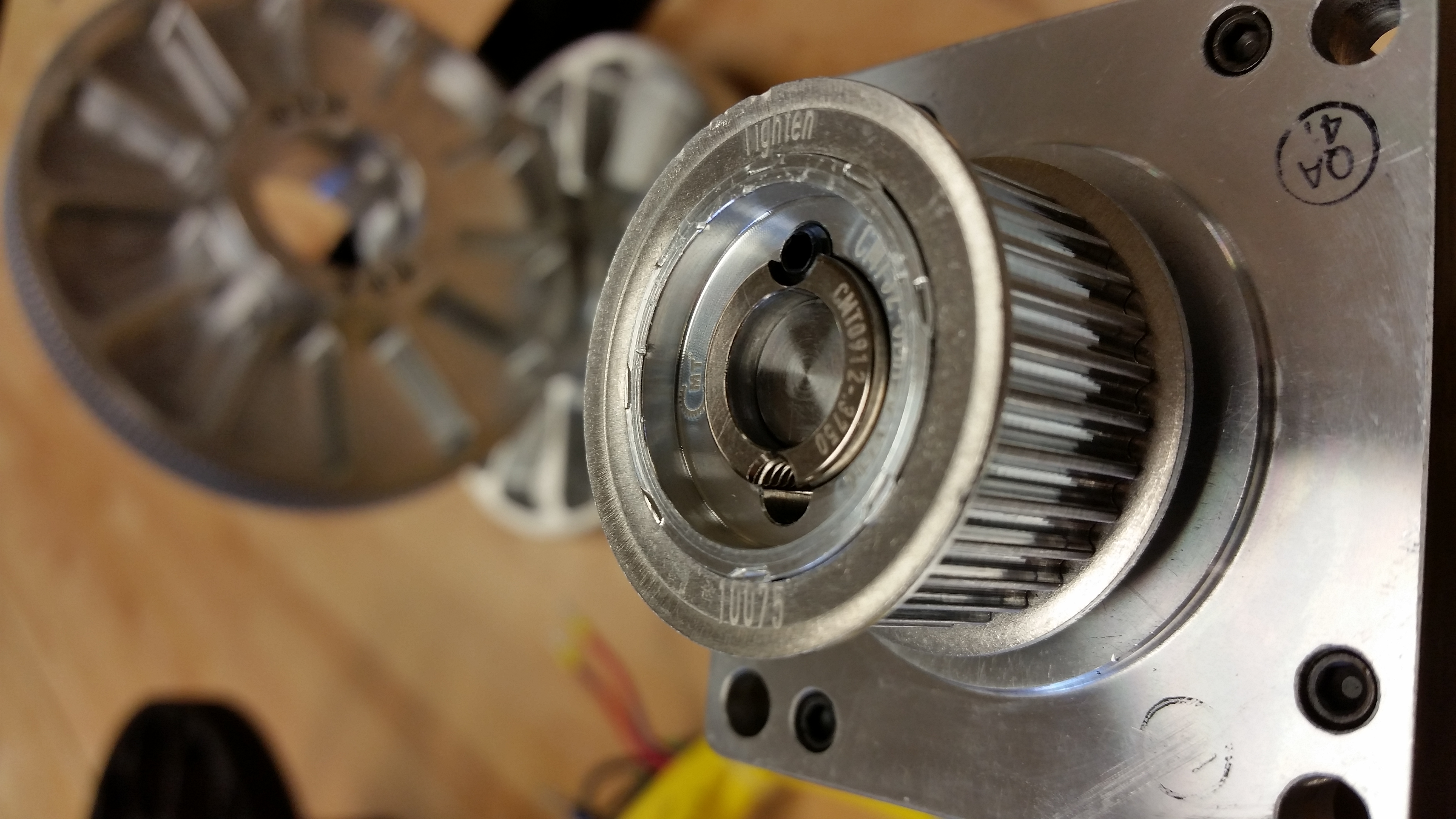

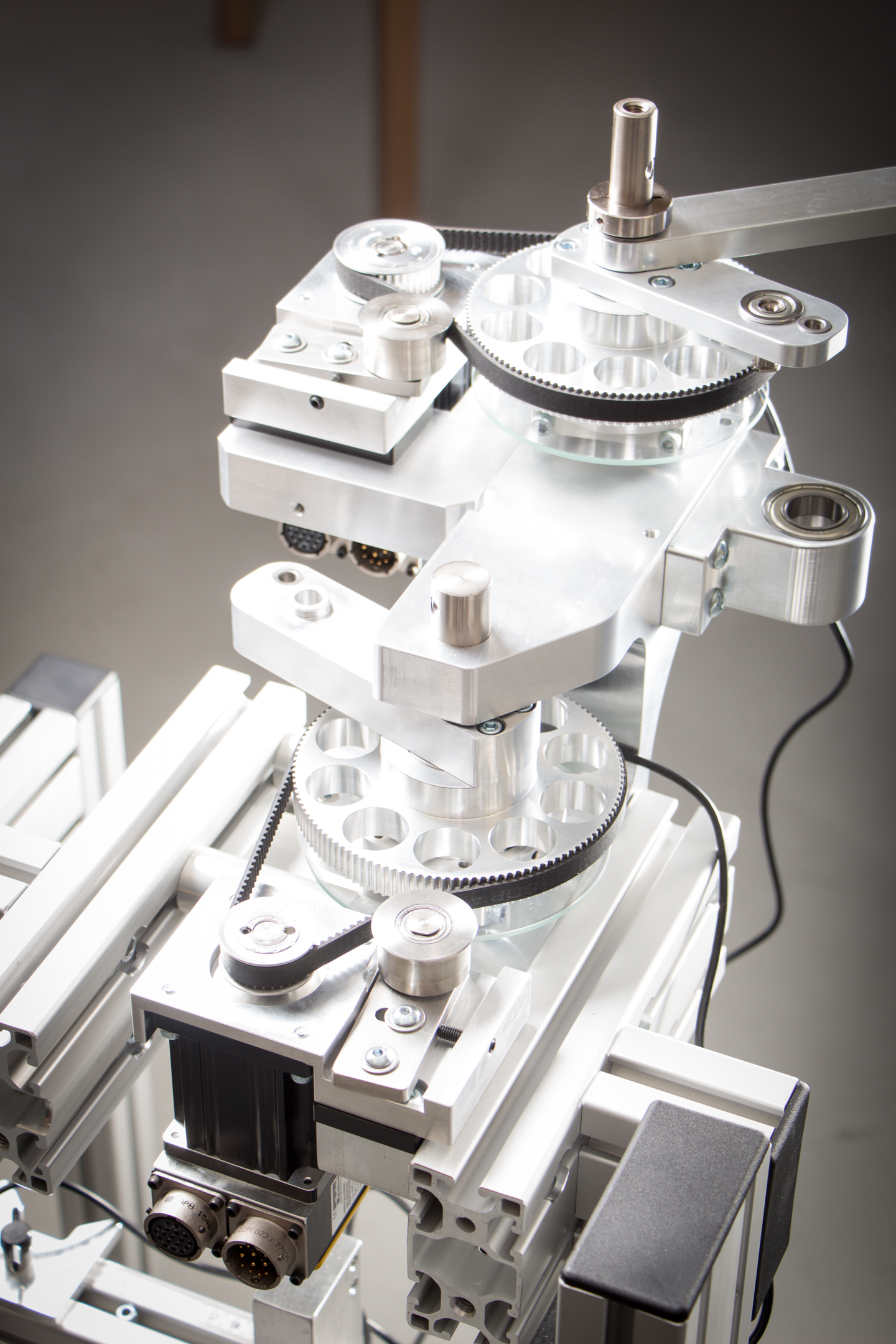

One of the major challenges facing Dr. Scott and his research and development team was the complexity of the robotic system itself. A robotic exoskeleton used to analyze human limb kinematics must not only be precise in every minute detail, but also allow a person in the lab to perform active, real-world actions. The key component that enables smooth, natural, non-jerky robotic movement is the slotless motor. This motor powers and drives the robot through a pulley and belt mechanism. The connection between the motor and the master pulley is therefore critical, requiring zero backlash and no slippage. The initial KINARM Lab design used a pulley that attached to the motor shaft using set-screws. The set-screws in the pulley loosened, resulting in backlash, shaft damage and eventual system failure. A viable coupling solution needed to be found.

CMT's Solution

After searching for a more reliable connection system that also offered a zero backlash guarantee, the engineers found CMT through an internet search. CMT was able design the Concentric Maxi Torque system into their pulley, eliminating the need for set screws, keyways and flats while generating zero backlash, even under heavy loads. Along with the additional benefits of its low profile design, which allowed for direct coupling to the motor shaft, its ease of positioning and the elimination of shaft damage due to its mechanical shrink fit, this connection system was the choice for the KINARM Exoskeleton Lab.

Need a solution for your challenge? Contact us at: info@cmtco.com.