Did you know?

Even though cardboard box packaging was used as far back as 1817, it wasn't until the turn of the century that corrugated boxes came online. As the result of an accident, Robert Gair invented prefabricated paperboard in Brooklyn, New York. While printing an order of seed bags, the metal ruler that was used to crease the bags slipped and cut them. Thus by cutting and creasing in one operation, Gair discovered he could create prefab paperboard boxes. The popularity of flaked cereals and “the best to you each morning,” skyrocketed the use of cardboard boxes as cereal cartons.

Customer's Challenge

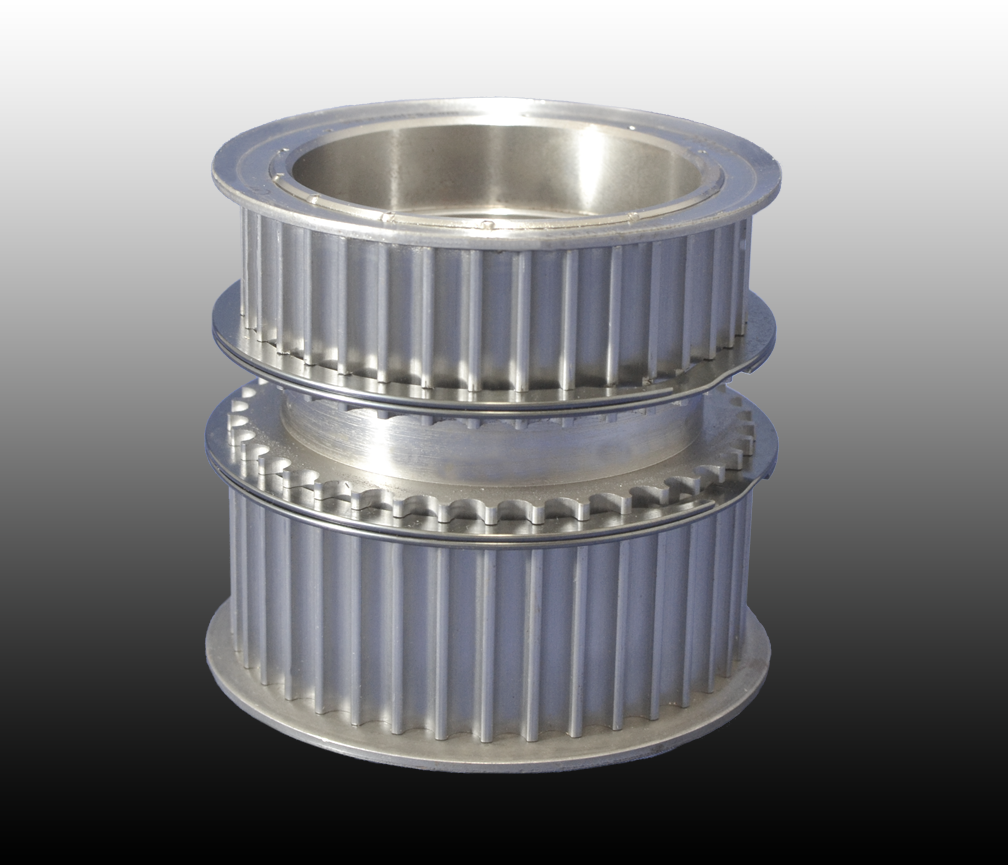

MarquipWardUnited, a manufacturer of finishing equipment for the corrugated machinery industry was bolting two idler pulleys of different widths and diameters together in an effort to run two drive belts within close proximity of each other. The bolted pulleys were unable to maintain concentricity and were a costly attempt at solving the problems.

CMT's Solution

By designing and manufacturing a dual idler pulley from one piece of material, CMT was able to supply a precision product that held concentricity and and reduced runout, extending the life of the product and the machine while saving the customer time and money.

Need a solution for your challenge? Contact us at: info@cmtco.com.