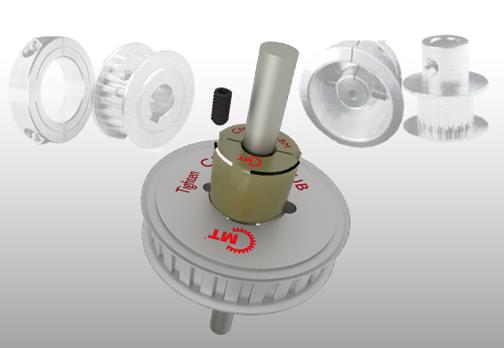

WHAT IS THE CONCENTRIC MAXI TORQUE?

-

CMT is a revolutionary keyless tapered bushing & shaft-to-hub connection system.

-

Developed initially for the synchronous drives market.

-

Designed and patented by Custom Machine & Tool Co., Inc.

WHY CUSTOM MACHINE & TOOL CO., INC. DEVELOPED THE CMT BUSHING SYSTEM

Custom Machine & Tool Co., Inc, through 40 years of design and application experience in the synchronous drives market, saw a need for a technologically improved hub-to-shaft connection system.

- As machine speeds and indexing requirements continue to increase reduction in inertia and vibration becomes important.

- Synchronous timing belts and system components will last longer, go faster and be more accurate when tension excursion is minimized through better run-out control.

- Component alignment and run-out are more critical at higher speeds.

- There was not a high quality compact bushing system available for shaft sizes under 1” diameter.

- Most connection systems require extra component mass to make the connection.

- Second and third generation synchronous timing belts are capable of production higher torques requiring stronger shaft connections.

CMT TECHNOLOGY

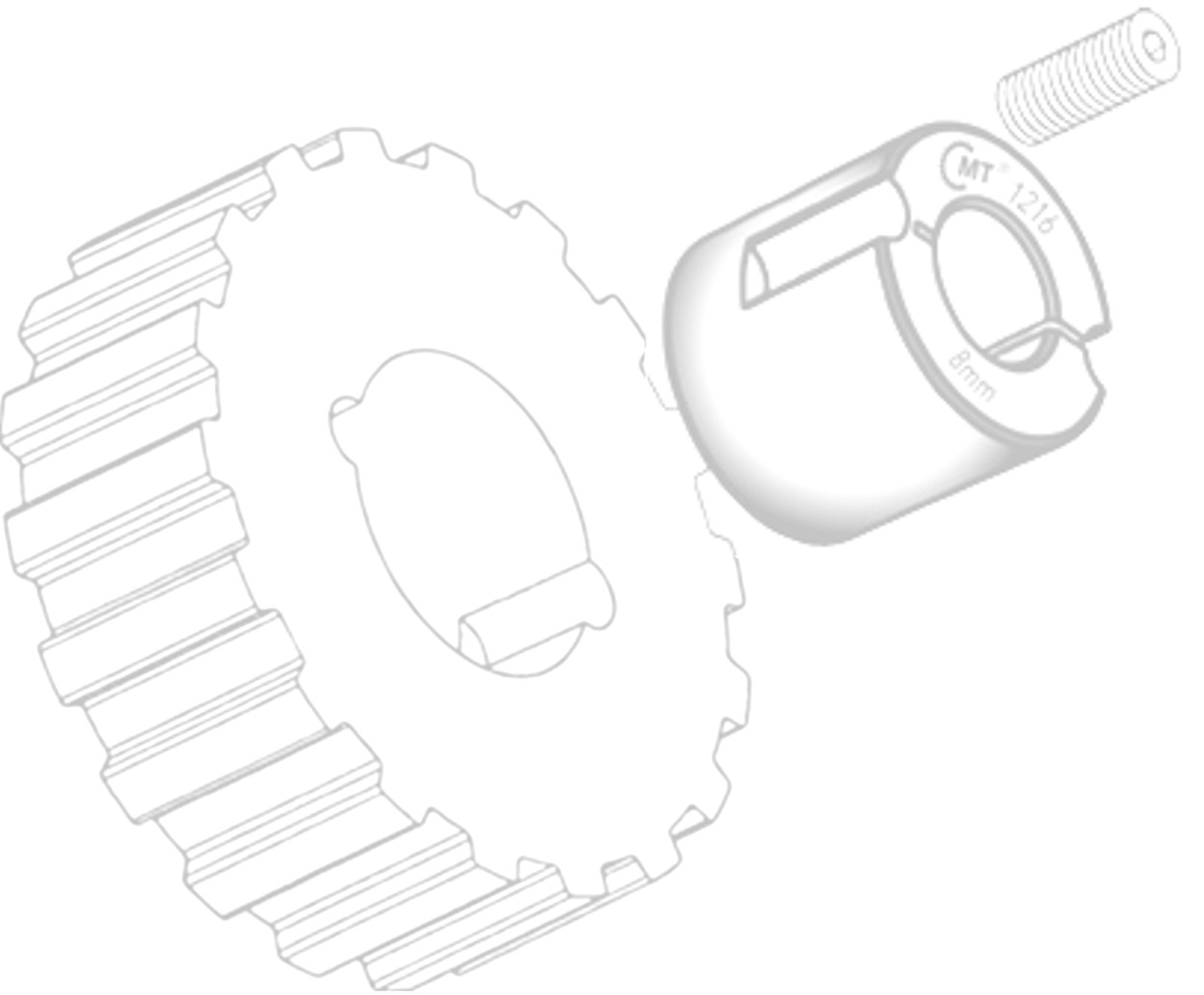

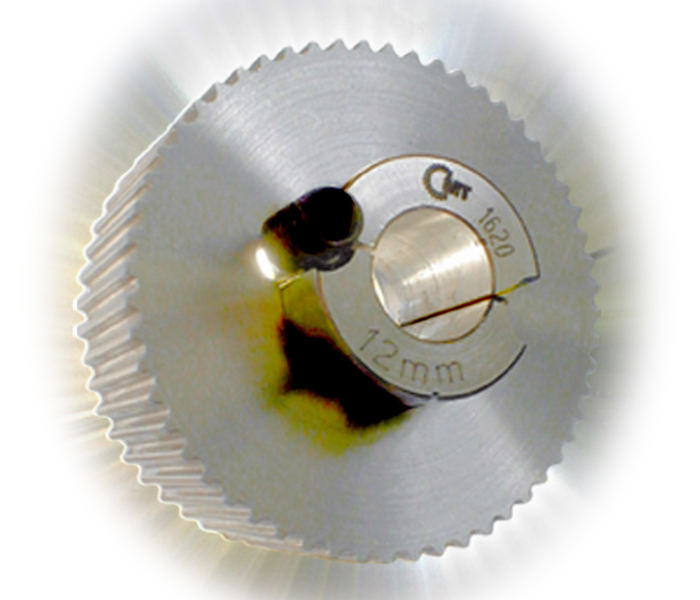

CMT is a unique bushing attachment system: a single set screw locks the low-taper-angle split bushing in place and eliminates all of the existing attachment issues.

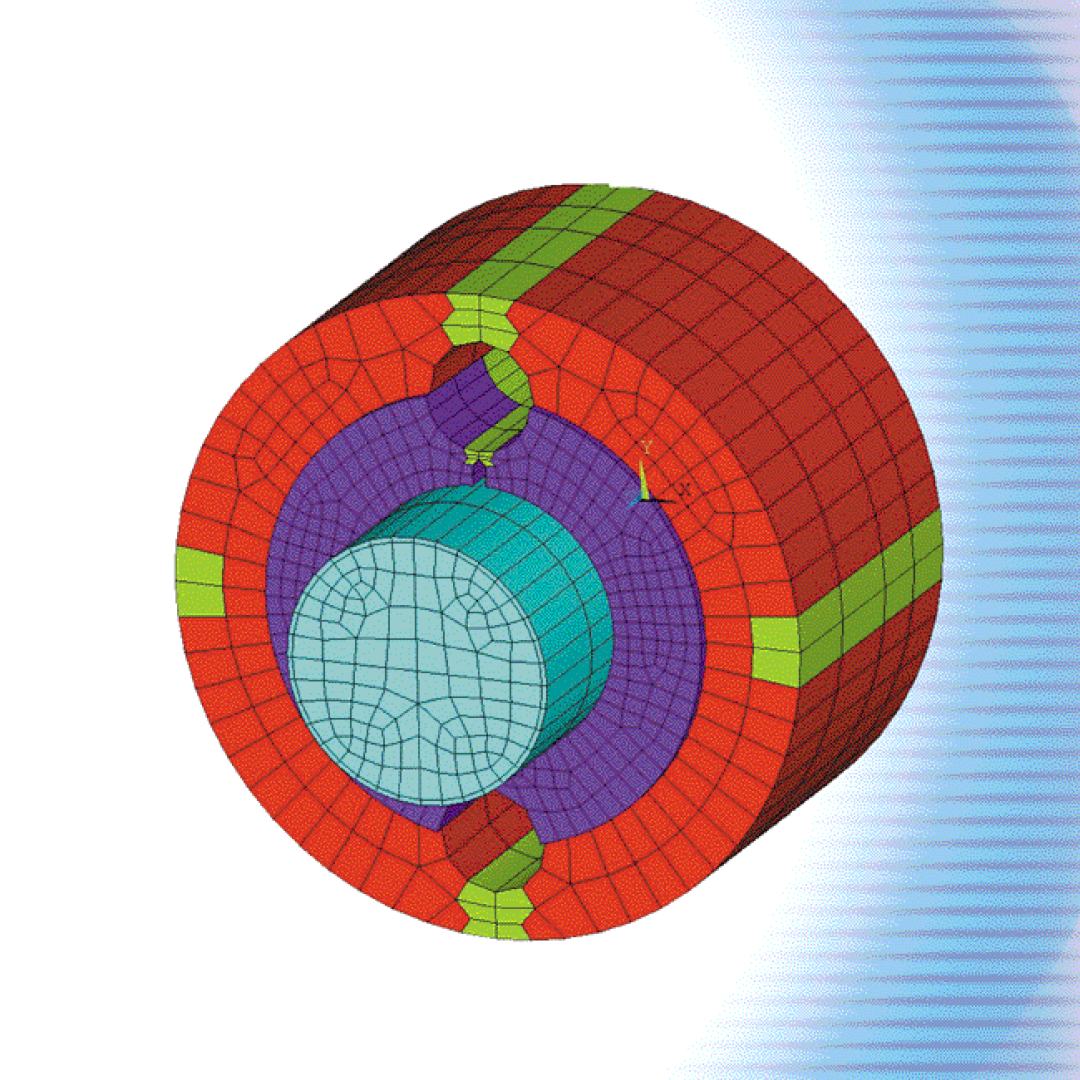

- Bushing system is engineered to assure full surface contact and even clamping pressure with a single set screw.

- Set screw size optimized to provide holding torque in line with shaft diameters and component torques

- Developed using mathematical and FEA modeling.

- Scalable to any shaft/bore size requirement.

- Lower inertia and better shaft-to-component balance.

- System design assures near perfect hub-to-shaft concentricity when assembled.

CMT BUSHING SYSTEM vs. OTHER SHAFT CONNECTION SYSTEMS

Easiest and fastest system to assemble and disassemble

CMT Bushing System Benefits

Set Screws: CMT has higher torque capacity, lower component run-out, better alignment, no shaft distortion.

Keyways: CMT has no movement under reversing conditions, maintains both axial and rotational position, allows for phase control during assembly, increased shaft contact decreases run-out.

Pins: CMT has higher torque capacity, decreased component run-out, phase control during assembly, easier assembly/disassembly, reusable.

Clamp Collars: CMT requires Less space, lower inertia, 360° uniform clamping pressure, lower cost, eliminates component wobble, multiple bore sizes per component.

Other Attachment Systems: CMT requires less space, lower inertia, lower cost, smaller outside diameter for minimum component size with maximum bore.

CMT PRODUCT FAMILY

Custom Machine & Tool Co., Inc. has developed its CMT bushing system, through scalable technology, to meet a wide variety of popular, as well as custom, hub-to-shaft combinations.

- Imperial & metric bore size coverage from .125” to 1.1875” and 3mm to 30mm

- Torque capacities from 14 in-lbs (1.5Nm) to 2,795 in-lbs (315 Nm)

- Multiple bore size offerings per bushing size allowing for maximum mix & match flexibility with minimum components

- Withstands repeated assembly and disassembly with no shaft damage and without a reduction in torque capacity

- Flexible positioning accuracy provides easy phase adjustment

CMT BUSHING SYSTEM APPLICATIONS

Custom Machine & Tool Co., Inc., an innovative designer and market leader, can apply the CMT bushing system in solving your most demanding hi-tech synchronous drive and rotating component problems.

- High speed indexing and reversing in systems using timing belt pulleys and gears

- Systems requiring a high level of component rotational positioning accuracy and precise run-out control

- Designs where reduced inertia and low vibration are desired

- Components required to be assembled and disassembled multiple times during their life

- Rotating mechanisms requiring compact space

- Devices requiring high reliability with minimal maintenance

CMT BUSHING SYSTEM PRODUCT OFFERING AND CUSTOM SOLUTIONS

We do it all in small to mid-sized timing pulley applications. Our manufacturing capabilities provide flexibility and low total cost solutions. We are specialists in product customization.

Timing Belt Pulleys

- MXL (.080”), XL (.200”), L (.375”), H (.500”)

- 3mm, 5mm, 8mm HTD® Profile

- 2mm, 3mm, 5mm, 8mm PGGT® Profile

- T2.5, T5, T10

- AT3, AT5, AT10

- 40DP (.0816”)

- Zero Backlash

Custom Products

- Idler Pulleys

- Round Belt Pulleys

- Feed Rollers

- Spur Gears

- Poly-V Pulleys

- Sprockets

WHERE CAN THE CMT BUSHING SYSTEM HELP YOU?

- Component Alignment and Timing

- Reversing Problems

- Inertia and Space

- Vibration Issues

CONCENTRIC MAXI TORQUE

A Technically Superior Solution

- Quicker assembly than other systems

- Higher holding reliability – lower maintenance

- Improved shaft-to-hub concentricity – less run-out

- Multiple bore sizes available per bushing size

- Reduced inertia for increased power savings

- Compact design fits in tighter spaces

- Cost competitive with all other attachment systems