Custom Machine & Tool teams up with Design World to sponsor their Pulley & Belts Design Guide

Pulley & Belt Drive Design Guide

Pulley & Belt Drive Design Guide

Learn about the basics of belt drives, design and performance considerations for various systems and the benefits of CMT’s Concentric Maxi Torque bushing system.

Wafer-Handling Machine Uses Specially Clamping Belt-Pulley and Bushing Assembly

March 2021

When Hine acquired and installed the Concentric Maxi Torque bushing system, they got an immediate increase in machine performance with enhanced repeatability and reliability.

Custom Machine and Tool Co., Inc. Bolsters Accuracy and Efficiency for Vande Berg Scales

Power Transmission Engineering

"It is a fantastic and very innovative product that makes complete sense for our needs," said David Vande Berg of Vande Berg Scales. "The Concentric Maxi Torque's smooth running power is key to the in-motion weighing system's performance."

Today's Approaches in Selecting Synchronous & V-Belt Designs

Design World

August 2017

Though they're versatile and forgiving, improperly sized friction-based belt drives can slip (tangentially on the pulley - a form of lost motion) and creep axially.

Using robotics to improve brain assessments

Design World

August 2016

CMT's Concentric Maxi Torque keyless bushing system has zero backlash and high clamping torques. Along with its low profile design, ease of positioning and the elimination of shaft damage due to its mechanical shrink fit, this connection system was the choice for the KINARM Exoskeleton Lab.

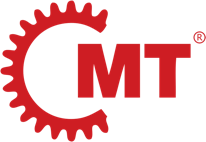

Tips on working with synchronous belt drives

Design World

May 2009

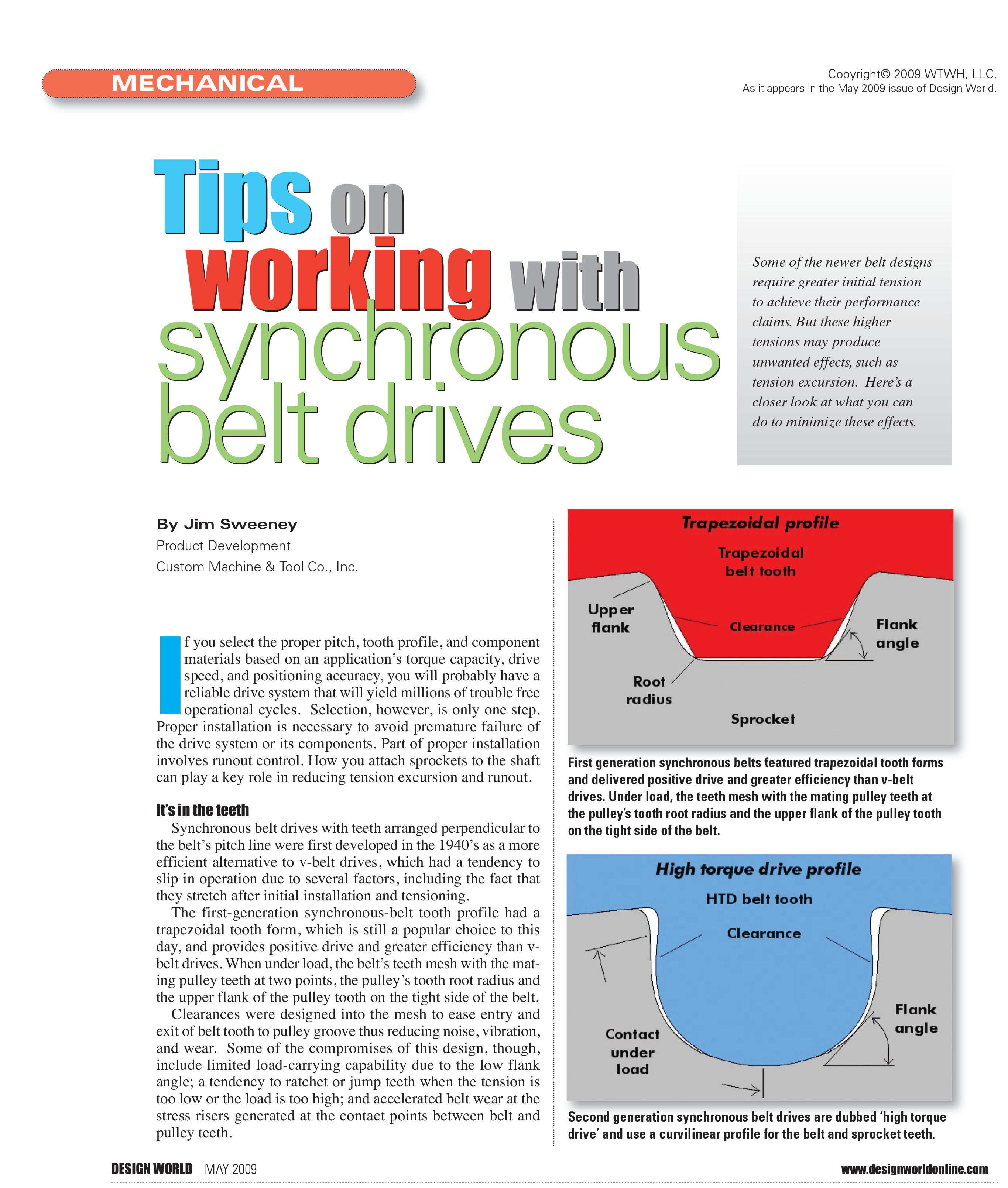

The most common method of shaft to hub attachment is two set screws at 90 degrees. To quote Dr. Woodie Flowers, Professor Emeritus and Director of the New Products Program at MIT's Mechanical Engineering Department, "Setscrews suck."