Did you know?

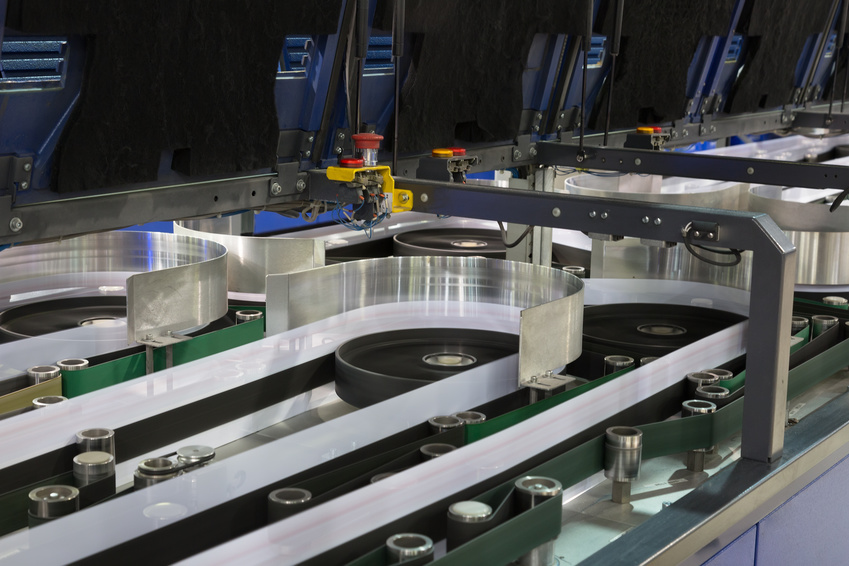

The labor intensive, time consuming, inefficiencies of “pigeonhole” mail sorting continued right up until the mid-20th century. It wasn't until 1959 that the first modern sorter came on line. By 1992, these machines became extinct as well, with the introduction of facer-canceler systems that doubled processing speed to an astounding 30,000 pieces per hour. And today? We are seeing multi-line optical character readers come into play that read the entire address on an envelope, spray on a barcode, then lightening-sort at more than nine pieces per second. Are you ready for tomorrow's breakthroughs? CMT is.

Customer's Challenge

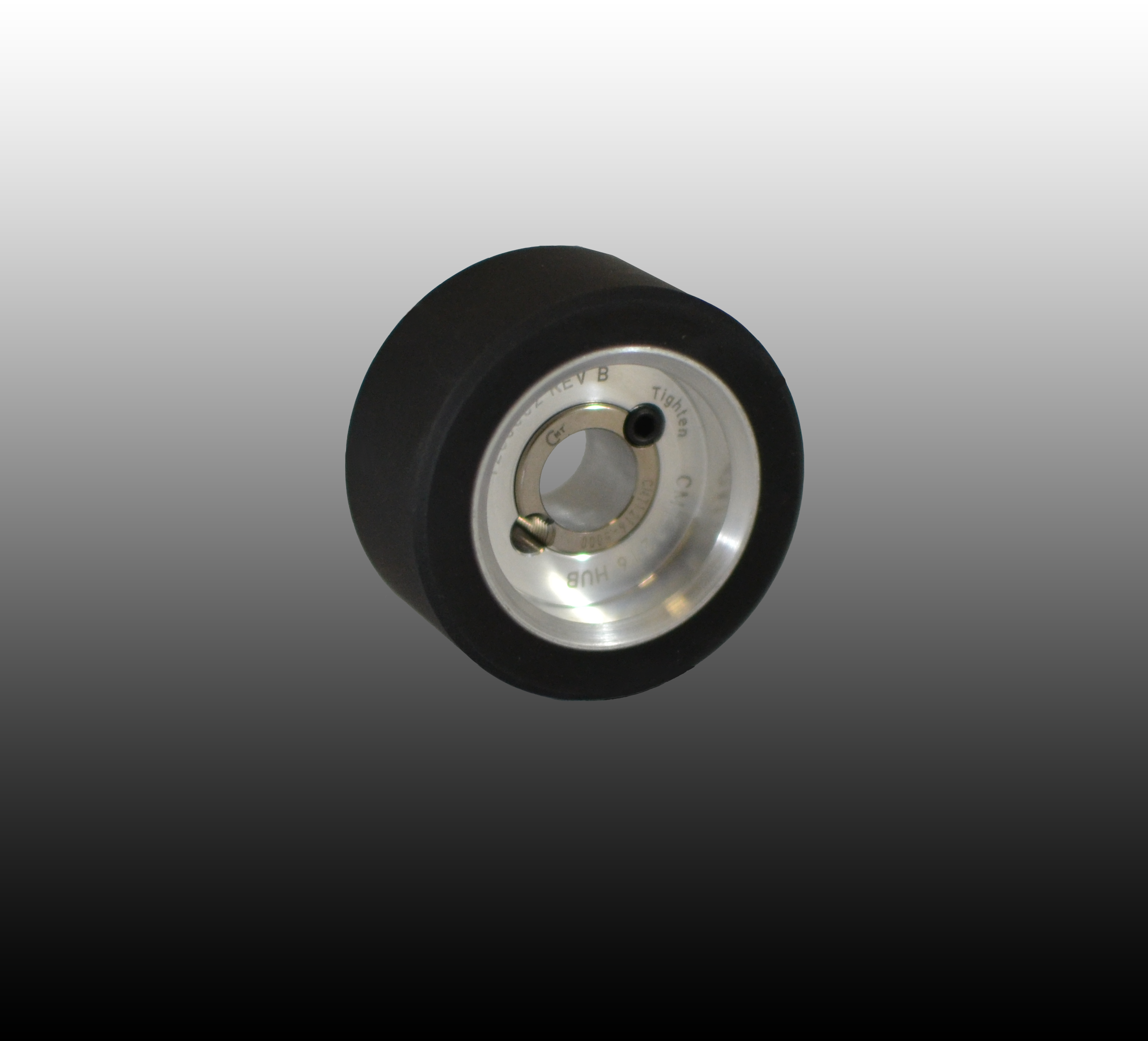

A global manufacturer of mail sorting equipment was using bulky, unreliable clamp collars to connect multiple drive rollers to a shaft within a paper handling system. The clamp collars added weight, contributing to performance problems due to increased inertia.

CMT's Solution

CMT redesigned the rollers to include the Concentric Maxi Torque connection system, eliminating the need for clamp collars and reducing the weight of the component. This resulted in a dramatic decrease in inertia and amp draw, enabling the machine to run more efficiently and lengthening the life of the product.

Need a solution for your challenge? Contact us at: info@cmtco.com.